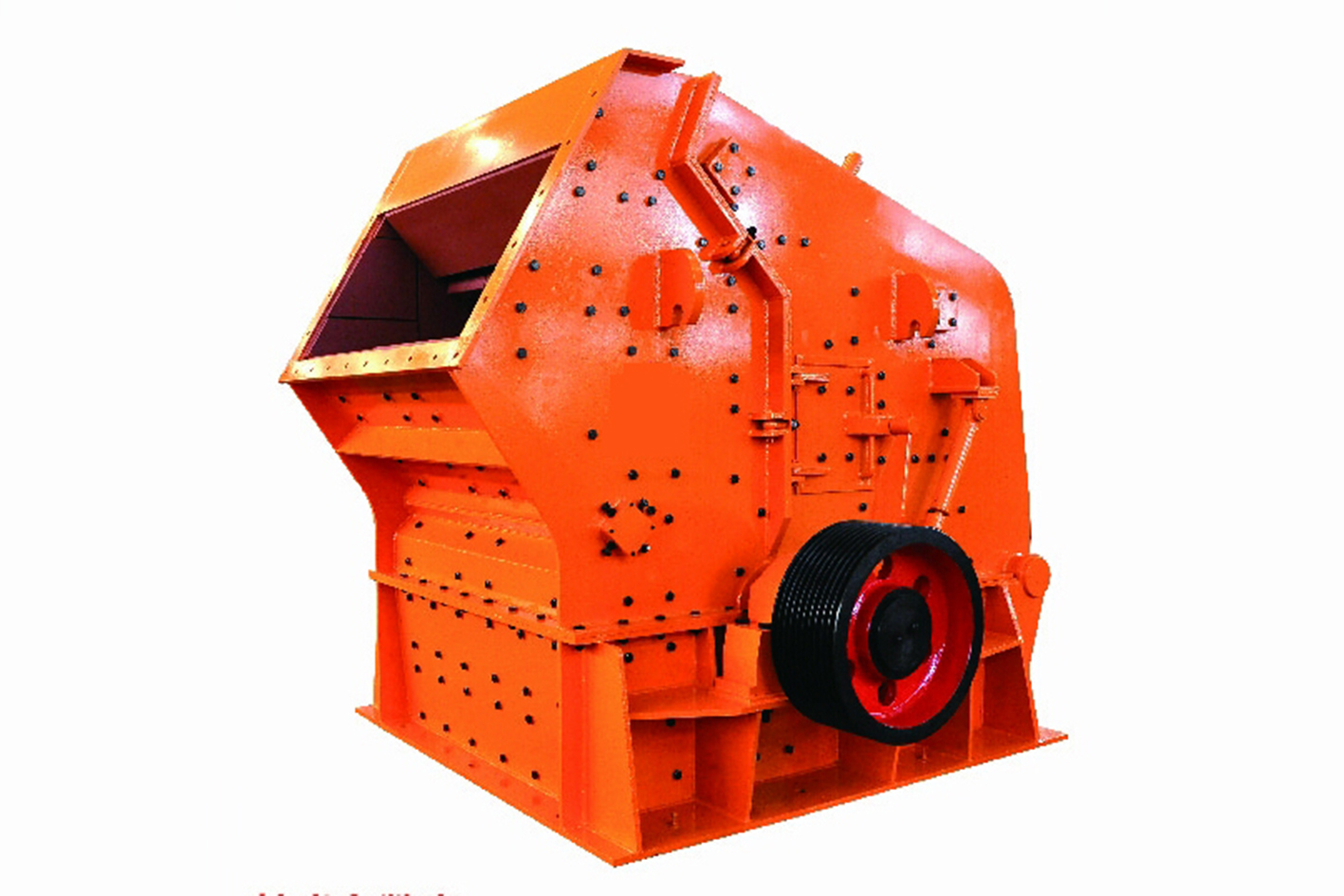

The PF impact crusher is a single-rotor impact crusher. The PF impact crusher designed and optimized by absorbing domestic and foreign advanced technology can process various materials with particle size and compressive strength not exceeding 360 MPa. It has the characteristics of large crushing ratio, high crushing efficiency and convenient maintenance. Its products are mostly cubic and uniform in size. It is an ideal processing equipment for aggregates used in high-grade road pavement and hydropower construction. With its excellent performance and good conuct, the impact crusher is widely used in highway construction, water conservancy projects and gravel processing in construction, chemical, coal, coke and other industrial sectors.

Structure:

The PF impact crusher is composed of a rear box, an impact liner, an impact track, a lining plate, a feed port, a base, a plate hammer, a rotor frame.

Working Principle:

The main working part of the impact crusher is the high-speed rotation with the plate hammer. The steering of the rotor is to make the hammer feed the material from the bottom of the feed port (The rotor steering of hammer crusher makes the hammer strike the material along the falling direction of the department). the material is impacted by the scoop, and was thrown at high speed into the counterattack plate in the casing, subject to a second impact. Then rebounded from the counterattack board and was hit again by the hammer. This process is repeated as such. During the round-trip impact, the material blocks also collide with each other. As the material is hit by the hammer, the impact of the counterattack and the collision between them, cracks are generated inside, loosened, and finally caused to break. When the material block is broken to a gap whose particle size is smaller than the hammer end and the counterattack plate, it is discharged from the gap.